Blog

Top Excavator Parts to Consider in 2025: Essential Buying Guide

As the construction industry continues to evolve, the demand for high-quality excavator parts is more critical than ever. In 2025, understanding which components are essential for optimal performance can greatly enhance the efficiency and reliability of excavation projects. Whether you are a contractor, a fleet manager, or simply a heavy machinery enthusiast, knowing the right excavator parts to prioritize will ensure that your machinery operates at peak performance and minimizes downtime.

When considering excavator parts, it is crucial to stay informed about the latest technological advancements and the materials used in their construction. With innovations emerging in durability and functionality, the correct selection of parts can lead to significant improvements in productivity and cost-effectiveness. This buying guide aims to provide insights into the most vital excavator components that should be on your radar as you plan your purchases for the upcoming year.

Focusing on areas such as hydraulic systems, undercarriages, and attachments, this guide will highlight key features to look for when selecting excavator parts. By making informed choices, operators can ensure that their equipment is not only compliant with industry standards but is also equipped to tackle the challenges of modern excavation tasks.

Key Factors to Consider When Choosing Excavator Parts

When choosing excavator parts, several key factors should influence your decision to ensure optimal performance and longevity. First and foremost, compatibility is crucial. Ensure that the parts you select are designed to fit your specific excavator model perfectly, as ill-fitting components can lead to inefficiency and damage over time. Additionally, consider the material quality. Parts made from durable materials may have a higher initial cost but will save you money in the long run by reducing replacement frequency.

Another important factor is the supplier's reputation. Look for suppliers with a history of providing reliable, high-quality parts. Online reviews and recommendations from trusted sources can be invaluable in assessing a supplier's credibility.

Tips: Before making a purchase, always check for warranty options. A solid warranty not only demonstrates the manufacturer’s confidence in the product but also provides peace of mind should any issues arise. Additionally, it's prudent to inquire about the availability of replacement parts in the future, as this can greatly affect your long-term maintenance strategy.

Essential Parts for Optimal Excavator Performance

When it comes to maximizing the performance of your excavator in 2025, focusing on essential parts is crucial.

The hydraulic system, for instance, is the powerhouse of the excavator.

It directly influences the machine's lifting capacity and overall efficiency. Regularly inspecting and maintaining hydraulic hoses, pumps, and cylinders ensures that your excavator operates smoothly and

reduces the risk of costly breakdowns.

Another vital component to consider is the undercarriage. This includes tracks, rollers, and sprockets, which are subjects to

wear and tear with heavy usage. Investing in high-quality undercarriage parts facilitates better traction and stability, significantly enhancing the machine's operational efficiency.

To prolong the life of these components, frequent checks and timely replacements are recommended, which can save on extensive repairs down the line.

Tips: Always keep a maintenance log for your hydraulic and undercarriage parts, noting any unusual sounds or performance issues.

Consider scheduling regular inspections by professionals to catch potential problems early. Additionally, keeping spare parts handy can minimize downtime,

ensuring your excavator remains productive on the job site.

Emerging Technologies in Excavator Parts for 2025

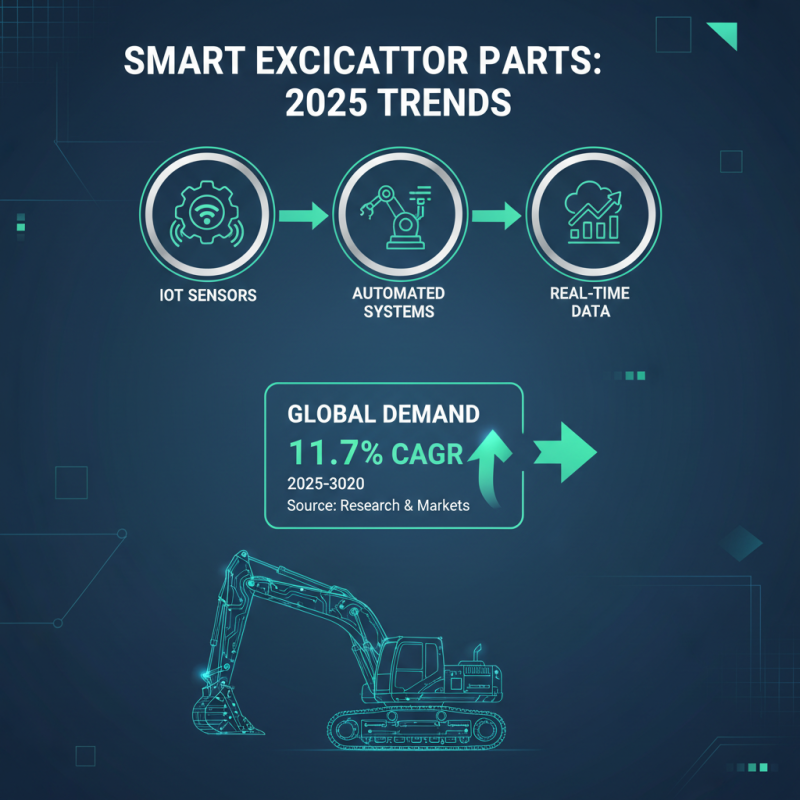

As we move into 2025, the excavator parts industry is witnessing a shift towards more advanced technologies that enhance efficiency and productivity. Emerging trends highlight the integration of smart technologies, such as IoT-enabled sensors and automated systems, which are designed to provide real-time data on equipment performance. According to a recent market analysis report from Research and Markets, the global demand for smart excavator components is projected to grow at a CAGR of 11.7% over the next five years, underscoring a clear move towards smarter machinery.

Manufacturers are increasingly focusing on energy-efficient components, such as hybrid engines and advanced hydraulic systems, which aim to reduce fuel consumption and lower emissions. A report by MarketsandMarkets indicates that the hybrid excavator market alone is estimated to reach $1 billion by 2025, driven by stricter environmental regulations and a growing emphasis on sustainable construction practices. Moreover, innovative materials like high-strength steel and advanced polymers are being utilized to enhance the durability and longevity of excavator parts.

Tips: When considering excavator parts in 2025, prioritize components that leverage IoT technology for enhanced diagnostics and predictive maintenance. This not only prolongs the lifespan of your machinery but also reduces unexpected downtime. Additionally, investing in energy-efficient parts contributes to long-term cost savings and aligns with global sustainability efforts. Embrace these emerging technologies to stay competitive in the evolving construction landscape.

Maintenance Tips for Long-Lasting Excavator Components

Maintaining excavator components is crucial for ensuring their longevity and optimal performance. Regular maintenance practices can significantly reduce wear and tear, allowing each part to function efficiently over time. Start by adhering to the manufacturer’s recommended service intervals for fluid changes and component inspections. Utilizing high-quality hydraulic fluids and lubricants is essential, as they help to minimize friction and protect critical components from damage.

Another important aspect of excavator maintenance involves monitoring the condition of wear parts such as buckets, tracks, and teeth. Regularly inspect these components for signs of excessive wear or damage and replace them proactively to prevent further issues. Keeping the machine clean, particularly around the undercarriage, can also help eliminate dirt and debris that can lead to corrosion and wear. By implementing a structured maintenance routine and keeping a close eye on key components, operators can extend the life of their excavators and enhance their overall productivity.

Top Excavator Parts to Consider in 2025: Essential Buying Guide - Maintenance Tips for Long-Lasting Excavator Components

| Part | Material | Maintenance Tips | Average Lifespan | Replacement Frequency |

|---|---|---|---|---|

| Bucket | High Carbon Steel | Regular wear inspections; sharpness checks | 5-7 years | Every 5 years |

| Hydraulic Hoses | Rubber/Metal | Regularly check for leaks; replace damaged hoses immediately | 2-4 years | Annually or as needed |

| Tracks | Steel | Inspect tension regularly; clean tracks to prevent wear | 8-10 years | Every 10 years |

| Swing Motor | Aluminum | Check oil levels; ensure clean cooling | 5-7 years | Every 5 years |

| Control Valves | Cast Iron | Regular inspection; keep free of dirt | 7-10 years | Every 7 years |

Cost-Effective Solutions for High-Quality Excavator Parts

In 2025, the excavator parts market is projected to grow significantly, driven by the construction industry's increasing demand for efficient equipment. According to a report from Global Market Insights, the excavator parts market is expected to reach USD 30 billion by 2026, with a compounded annual growth rate (CAGR) of 5.6% from 2021 to 2026. This presents a prime opportunity for buyers to invest in cost-effective solutions that do not compromise on quality.

When considering excavator parts, it’s essential to focus on those that enhance the machine's lifespan and operational efficiency. Cost-effective solutions are particularly vital in a landscape where maintenance budgets are often squeezed. Research from the Construction Equipment Market Report indicates that over 30% of maintenance costs are directly attributable to parts that are subpar or not tailored to the needs of the equipment. Thus, emphasizing high-quality components can lead to reduced downtime and enhanced productivity, resulting in long-term savings.

As the competition intensifies in the construction sector, buying smart means looking beyond just the price tag. Choosing the right excavator parts, which may include hydraulic pumps, tracks, and filters, provides a balance of performance and affordability. A strategic investment in these essentials can drive not just immediate operational needs but also future-proof equipment against the backdrop of evolving industry standards and technology advancements.

Related Posts

-

Future Trends in Best Excavator Parts Market Analysis for 2025 with Real World Examples

-

Emerging Trends in 2025: Innovative Solutions for Best Heavy Equipment Parts

-

How to Select the Best Con Equipment Parts for Your Global Sourcing Needs

-

Understanding the Importance of Con Equipment Parts in Modern Construction

-

Embracing 2025 Tech Trends: Best Heavy Machinery Strategies for Future-Proofing Your Business

-

Transforming Construction Sites with the Best Heavy Equipment Parts for Efficient Operations